We have developed various systems in the past as individuals however developing a product that can be used to manufacture anything and can be used in almost any product development facility for us as techies is an honor.

Kreator 3D is a Chennai-based startup that manufactures 3D printers, it was founded by Anurag Atulya and Shubham Dawkhar while they were students at the SRM Institute of Science and Technology. Anurag and Shubham along with their team put in a lot of hard work and incredible knowledge into their work with a goal of making 3D printers a household item that can be used by everyone for their specific needs. They also aim to run a service that prints 3D parts for those who need them in the future. In conversation with Anurag, Co-founder of Kreator 3D, we learn more about the story behind Kreator 3D, the core team and their future plans for the startup!

Chennai Insider: Give us a brief on what Kreator 3D is about.

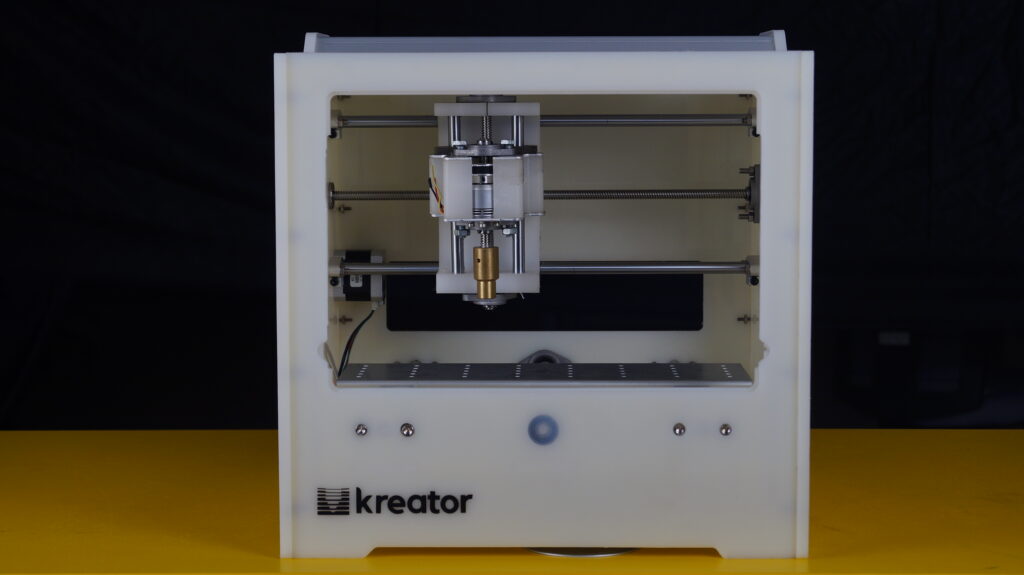

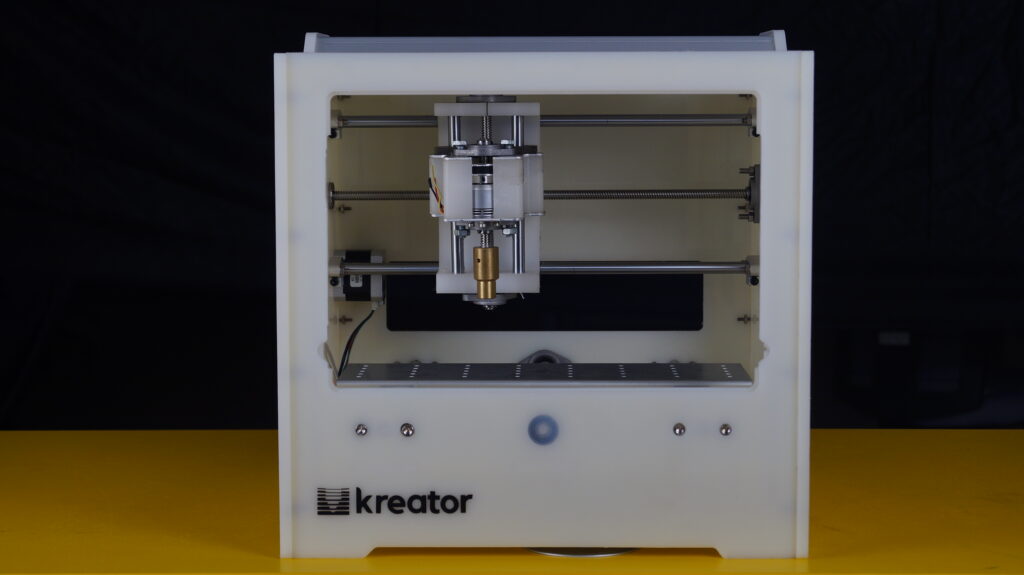

Anurag: We at Kreator 3D develop 3D Printing technologies and create 3D Printers which are completely designed and conceptualized in India and is cloud connected and very intuitive to use. We have also been developing 3D Printing technologies to expand into various other fields such as Metal, Composites, Biomaterials. Our goal is to help everyone own and use 3D printers in their own unique way!

Chennai Insider: What made you start Kreator 3D? What is the story behind it?

Anurag: We are Kreator 3D, a Startup in the manufacturing space based out of Chennai. The journey started about 3 years ago. We had bought our first DIY 3D Printer and the setup phase was very difficult. Things started failing and needed constant repairing and tweaking for even the simplest objects. After a while, we decided to make a new one from scratch and we focused on all the problems we faced with our first printer and succeeded in solving the initial problems. We then proceeded to making innovations of our own to make sure our customers don’t go through our experiences with 3D printing and we are now better than most industry standard printers. It however didn’t look like a desktop printer that everyone would own. We focused on design and with the aim that Kreator printer owners would be proud to own a piece of technology sitting on the desk like our product. We kept on doing the same and by the end of 2018, we decided to make it into a startup. Around April 2019 Kreator 3D was incorporated.

Chennai Insider: Tell us about the products at Kreator 3D. Could you briefly explain the process of 3D printing for our readers?

Anurag: We currently develop 3D Printers using the FDM Technology. This is melting and laying plastic in form of line to form surfaces and to print multiple surfaces on top of each other to create a 3D Object. Changing various parameters such as the width of the line and the height of each layer gives the customer to a tradeoff between the print quality print time.

Chennai Insider: Could you tell us how Kreator 3D’s Ventilator came to being?

Anurag: We have been developing 3D Printers for a while now. The directors in the company have also worked on various other systems in the past. After having a look at the ventilators that had started to develop in the market and being locked out of our offices due to lockdown, with the ample amount of time at our hands we figured that building something like this won’t be difficult. We approached SRM Hospital regarding the same, got information about what is required from the doctors and started building the same. The further development was assisted by our Incubation center (SRM Innovation and Incubation Center) and the resources and facilities including the permission to work during lockdown were arranged by the Incubation Centers Fablab.

Chennai Insider: Where is your startup based out of? Why do you think that is the best place for you?

Anurag: We have been working out of our office at the SRM Innovation and Incubation Center located at the Kattankulathur of SRM Institute of Science and Technology. We have been fortunate to be incubated here at the resources available to us working here have helped us accelerate our development in the initial stages when resources and equipments were a problem for us. We plan to expand our office, production facilities and staff soon however as labor, factory space etc are at an affordable rate in the nearby region being in the suburbs this location in the initial stages has turned out to give us maximum output with minimum investment.

Chennai Insider: Have you raised funding? If yes, then we would like to know the details. If no then please tell us if you’re looking to raise?

Anurag: We are in advanced stage of discussion with a private mentor and investor who has been in the tech space for a while. He will bring strategic guidance on many a fields including go to market strategy along with the requisite funds.

Chennai Insider: What gets you excited about this company?

Anurag: We have developed various systems in the past as individuals however developing a product that can be used to manufacture anything and can be used in almost any product development facility for us as techies is an honor. We have been working hard to make this product perfect to the final T and we ourselves being a part of the target consumer category makes us work even harder.

Chennai Insider: Tell us about your team and how did you meet each other?

Anurag: We as individuals were working on various projects since our admission in SRM Institute of Science and Technology. Anurag worked on 3D Plotters and many other projects however to complete his projects without having to make it fail or look bad he purchased a 3D Printer. Shubham was Anurag’s classmate and had been working on developing autonomous systems in the marine domain at the time. They used to have frequent discussion on each other’s projects and helpes each other out sometimes. This friendship turned into the incorporation of Kreator. Sabyasachi was a very frequent customer of Anurag and used to get parts printed for his projects. He had been working on hyperloop at that time. He had some brilliant ideas to be implemented in 3D Printing and thus he joined Kreator. Zeeshan was working on Autonomous Underwater Vehicles and was quite brilliant in designing various mechanisms to make things work. He started as mutual friend but the common interest into manufacturing soon made him a close friend and ended up being a part of Kreator 3D.

Chennai Insider: What are your future plans for Kreator 3D, where do you see Kreator 3D in the next few years?

Anurag: We are currently in the final R&D stage. However, what’s been discussed internally is this, we intend to start with two biz models.

- Sale of 3D printing machines

- Run it as a service by offering to print 3D printed parts to people who require the same.

In the future we wish to add collaboration with retail chain as well in which we wish to have our machines placed in electronic retail chain stores across the country whereby anyone could walk in these retail stores and print any part using our 3D printing machine. We wish to make 3D printing a house hold necessity. The market for 3D printing and 3D printed parts has not even started. BIG Leap is yet to come. We are right on time and surely at the right place too 🙂

Chennai Insider: What is the one thing that sets you apart from your competitors and what’s your revenue model? – Who are your key clients? How much do you charge them?

Anurag: In the manufacturing space, machines with high precision, industry standards and yet blending in perfectly with your workspace, silent and easy to use with a fully connected and functional interface is not found. This creates a gap between the innovator and his product being manufactured. We have got that covered. We, as an innovator, have built a product which helps in reducing the time to market. We are yet to start the sale of printers and printed parts. It would be right to say we are in the last leg of go to market.

Chennai Insider: Give us a background of your core team and yourself with the age.

Anurag: I am a student from electrical engineering with a passion for manufacturing. I am currently 22 years old and I have a deep knowledge of various machining and process in manufacturing space.

Shubham Dawkhar, He is a student from electrical engineering with passion in control systems. He has been the Team Lead for Team SRM ASV from 2018-2020. He is 22 years old currently.

Sabyasachi Gosh, He is a student from mechanical engineering. He is passionate about materials composites and designing them to manipulate and achieve certain required properties required. He has been the technical director of Infialpha Hyperloop team in SRM form 2018-2020. He is currently 22 years old.

Zeeshan Mallick, He is a student from Mechatronics engineering with a passion design of complex mechanical mechanisms and product design. He has been the team lead of Team SRM AUV from 2018-2020. He is currently 22 years old.

Animesh kumar singh , He is a student from mechanical engineering with passion of product design and development. He is currently 19 years old.

We would love to hear from you! Know a great story or want to tell us your own? Write to us at amia@insidermediacorp.com and we will get back to you. For more updates follow Chennai Insider on Facebook and Instagram.